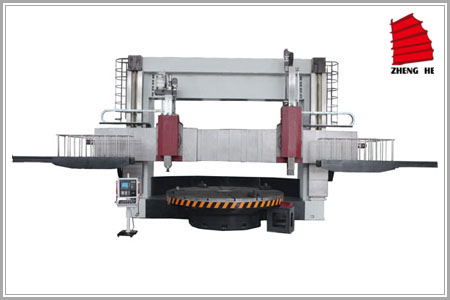

CXK5240 CNC turning center

1. CXK series CNC vertical turning and milling center was developed by our

company independently. The new product is multi-function, high-precision,

high-efficiency compound machine tools. This machine is widely used in

military project, aerospace, shipbuilding, nuclear power, railway, etc with

advanced technology, yield efficiency, processing precision.

2. CXK series CNC vertical turning and milling center not only own the functions

that convention CNC vertical has. All process except undersurface can be

finished with one time clamping, such as turning, milling, boring, tapping, etc.

Many kinds of more complicated curved surfaces, such as vane, can be also

conducted with, if double swing milling head is set up. It has x and z axis,

c three CNC for triaxial linkage.

3. The main components and main transmission adopts thermal symmetrical

structure, with high thermal stability.

4. Worktable main shaft adopts high-precision double row cylindrical roller

bearing for centering in radial direction, and adopts large ball thrust bearing for

loading in axial direction. Worktable is provided with the functions of precision

indexing and turning and milling feedings.

5. The beam has hierarchical positioning function.

6. The ram adopts high-precision ball screw transmission.Machine is setup with

ATC with12-20 tool station.

7. Siemens 840DSL system (user can appoint other system) is adopted; servo

motor and servo driver all utilize Siemens products.

8. All the castings are made of HT300 gray cast iron(ram is made of ductileiron)

which is treated with artificial heat aging, high-quality processing and improved

assembly process. All the electrical parts, bearings, key parts, hydraulic parts

were picked from the international famous brand manufacturers.

9. Complete fitting configuration allows the user to put into operation only bypreparing

cutting tool and measuring tool, with perfect after-sale service, 2 years

quality service.

|